The Troubleshooting and Maintenance of Grounding and Bonding: A Comprehensive Guide

The Need for Troubleshooting and Maintenance

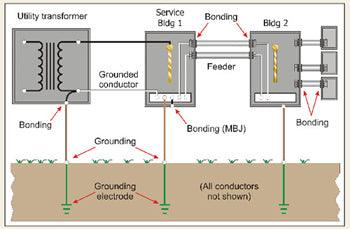

Grounding and bonding are crucial elements in any electrical system, and both need regular troubleshooting and maintenance. Issues with either of these components can lead to electrical malfunctions or even safety hazards, such as electrical shocks or fires. Regular checks and maintenance can help prevent these risks and ensure that your system remains in line with NEC compliance.

Troubleshooting Techniques

Diagnosing faulty grounding or bonding involves a few different techniques. These include continuity testing to ensure that there's an unbroken path for the electricity to follow, and ground resistance testing to measure the effectiveness of your grounding system. If the continuity test fails or the ground resistance is too high, it indicates a problem that needs addressing.

Maintenance Procedures

Proactive maintenance procedures include regular inspections of the grounding and bonding systems. These inspections should include checking the physical condition of wires and connections, verifying the tightness of connections, and testing the system's functionality. It's also crucial to keep a grounding and bonding maintenance schedule, to ensure regular checks are not missed.

Repairing Grounding and Bonding Issues

If a problem is found during the troubleshooting process, it's important to act swiftly to make necessary repairs. This may involve replacing damaged wires, tightening loose connections, or installing new components to improve the overall function of the grounding or bonding system.

Maintenance Best Practices

Maintenance best practices include regular testing and inspections, swift repairs of any issues, and keeping up to date with NEC requirements. Adhering to a maintenance schedule is key, and having a grounding and bonding maintenance checklist can make this process easier and more effective.

Balancing Factors in Troubleshooting and Maintenance

In troubleshooting and maintaining grounding and bonding systems, there's a need to balance various factors. This includes the cost of maintenance and repairs against the need for safety, the urgency of repairs against the availability of resources, and the need for ongoing maintenance against the requirements of the electrical system.

Conclusion

Effective troubleshooting and maintenance of grounding and bonding systems are essential for the safe and effective operation of any electrical system. It's crucial to follow best practices, adhere to a regular maintenance schedule, and ensure swift repairs of any identified issues. Trusting professionals for these tasks is always a smart choice.